Fabrication and Coordination Modeling

The fabrication team has vast experience in using Fabrication and Revit to develop constructible models to fabrication.

Key Services and Solutions

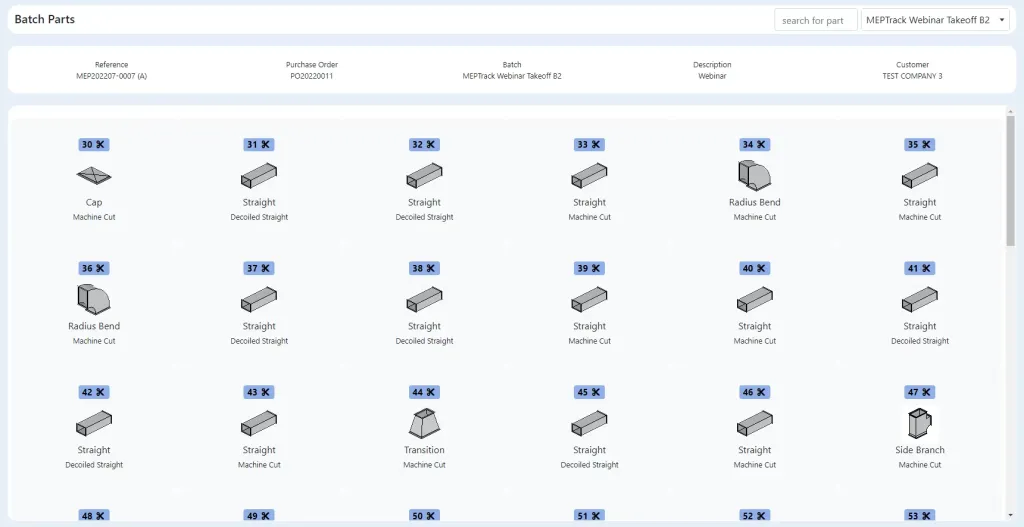

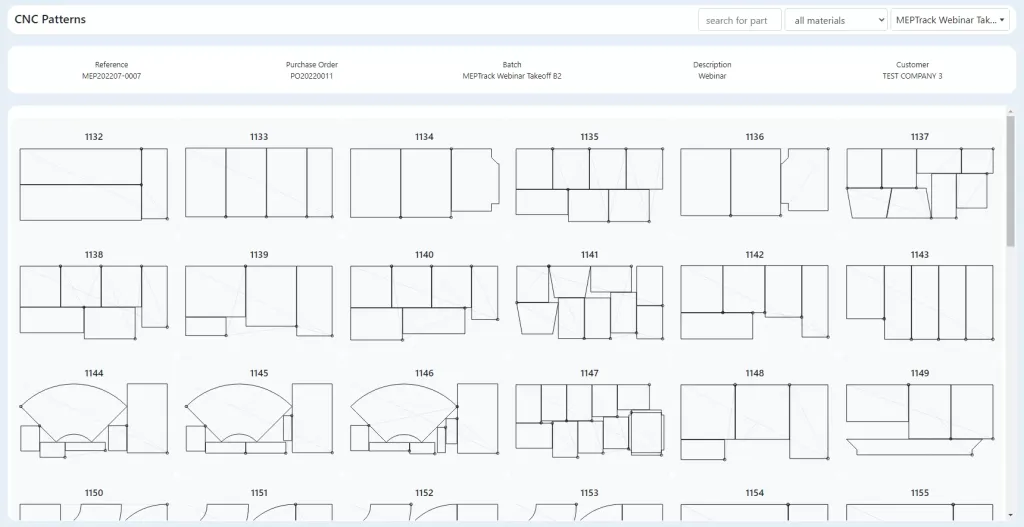

BIM for Prefabrication and Fabrication

Preparing a building component or assembly for fabrication is time-consuming and complex. BIM facilitates various design and construction activities, including digital fabrication and installation drawings. It enables digital design-to-fabrication workflows for all building disciplines. ENGworks Global prides itself on a comprehensive fabrication database developed over 10 years, allowing for detailed spool drawings used in pre-fabrication. We can also use customer-specific databases to generate spool and installation drawings. Our fabrication team has extensive experience producing accurate shop and fabrication drawings across multiple trades, including Structural, MEP, and Civil. They are proficient in using Fabrication CADmep and Revit to develop thorough constructible plans.

Design Assist

ENGworks Global/D&D Engineering is a forward-thinking, full-service consulting engineering firm specializing in innovative MEP design, energy management, and conservation solutions. Our goal is to improve the built environment with high-performance designs that balance environmental and user concerns, constructability, schedule, and budget through thoughtful, integrated engineering solutions. ENGworks Global has consistently invested in technology, leading the MEP community in adopting CAD, 3D, and Building Information Modeling (BIM). Integration is crucial not only in engineering processes but also in fostering relationships among all stakeholders throughout a building's design, construction, use, and maintenance. The best way to achieve optimal solutions is through close collaboration, early design decision-making, and process integration.

Building Conflict Reporting / Clash Detection

Once the BIM Models for all disciplines are created, ENGworks Global performs Clash Detection and generates customized Building Conflict Reports (BCR). Our staff collaborates with architects, engineers, general contractors, and trades to resolve design conflicts before construction begins.

We use Autodesk® Navisworks Manage® Software and other platforms for precise collision detection and clash reports. Multiple CAD/BIM platforms can be imported into a single, lightweight file. Each BCR is uploaded by trade for all parties to see, issues are documented, and project schedules updated. We also provide hardware and software for turnkey solutions.

Key benefits include:

- Increased transparency in design decisions

- Reduced construction costs by identifying and correcting clashes early

- Higher chances of winning project bids with thoughtful design visualization

- Fewer change orders, reducing administrative expenses and processing time

- More off-site fabrication, improving yard management activities.

DfMA

Design for Manufacturing and Assembly benefits the General Contractor/Owner by increasing field productivity and reducing schedule and cost. ENGworks teams coordinate the MEP trades within the EOR design models during the design phase. We replace duct and pipe components with accurate Revit fittings, add insulation and pitch systems, and ensure systems are clash-free, including hangers and equipment access. This process identifies and resolves issues early, confirms ceiling elevations, and generates deck penetration layouts. Multi-trade racking enhances efficiency during prefabrication and field activities.

Key benefits include:

- Reduction in the amount of time and cost associated with RFIs

- Preplanned structural penetrations

- Accurate quantity take-offs for true estimating during bid process

- Shorten project schedule

- Increased cohesiveness between Design and final installation drawings

- Eliminate code violations and constructability issues during design

- Reduce change orders

- Minimize subcontractor BIM responsibilities/Requirements

- Reduce onsite delays

Estimation and Fabrication Databases Services

CAMduct – Manufacturing /Material Costing / Labor Cost

- Database Configuration

- Database Migration (Pre Autodesk PM2000 to Fabrication 2023)

- Database Auditing

- Plasma / Insulation / Laser / Router / Coil Line configuration

- Post Processor customization (some Limitations depending on machine controller)

- Setup Seam / Connector / Notch / Ancillary (Damper Blade – Turning Vane)

- Quick Takeoff Training

- Interface Training

- Report Building

- Label Configuration

- Material Costing

- Item Customization

- Product List Creation

- Deep Dive – Database management

- Job Setup & Saving

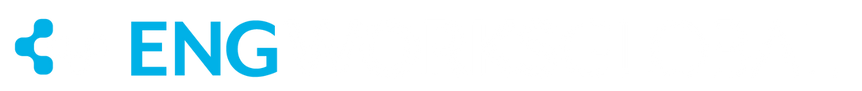

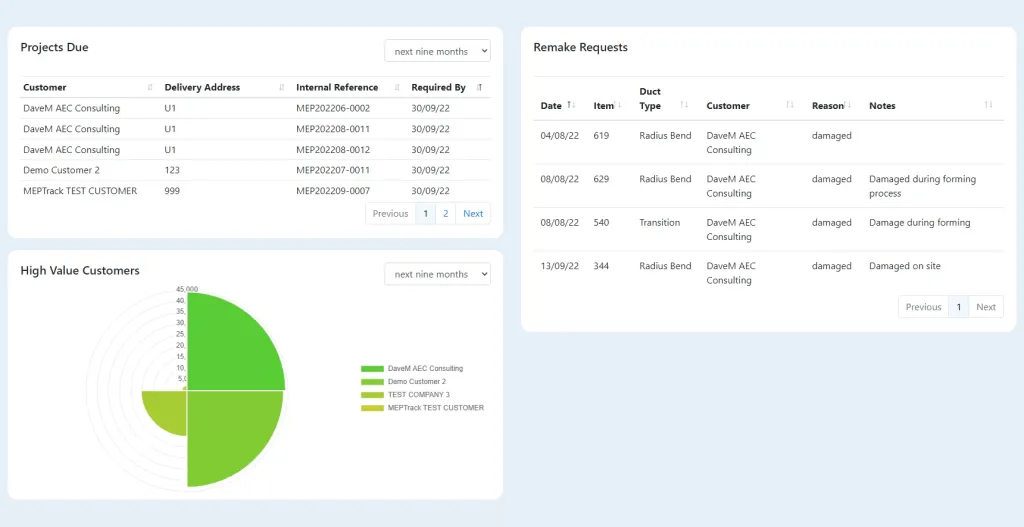

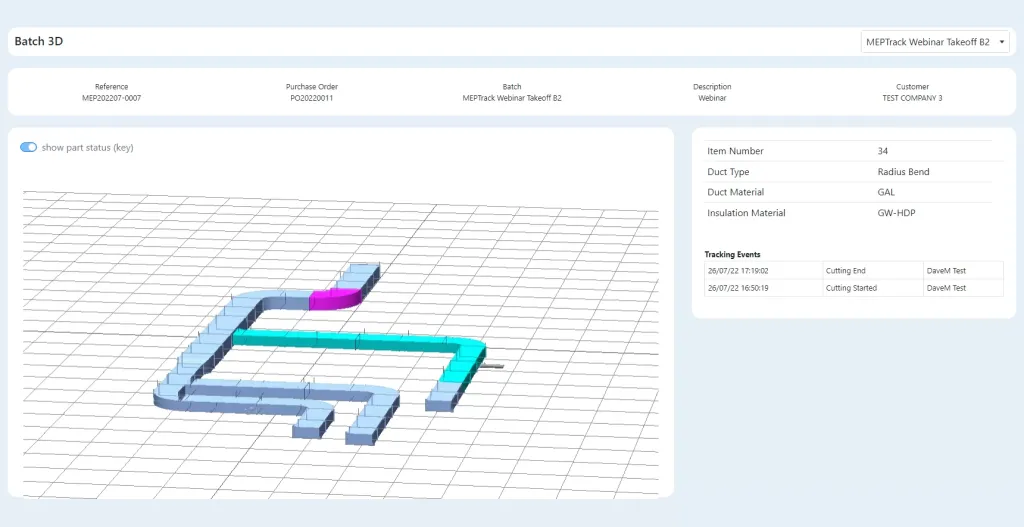

- MEPTrack Cloud Reporting Export

Need a Fabrication Database? Check Out our FAB360 Configurations here.

CADmep – Design / Coordination / Detailing

- Customized Fabrication Databases

- Database Configuration

- Database Auditing and Repairs

- Fabrication Design Services and Templates Creation

- Database Administrative Training and Consulting

- FAB360 Databases Solutions

- Reports and Profile Setups

- Product List Creation

- Fabrication Parts in Revit Consulting

ESTmep – Design / Estimation / Bid / Validation

- Database Configuration

- Database Migration (Pre Autodesk PM2000 to Fabrication 2023)

- Database Auditing

- Granular Costing Setup

- Design Line Takeoff Training

- Quick Takeoff Training

- General Interface Training

- Report Building

- Material Costing

- Deep Dive – Database management

- MEPTrack Cloud Reporting Export

REVIT – Design / Coordination / Detailing

- Database Importing

- Best Practice Workflows In Revit

- Design To Fabrication Exchange

- Multi-Point Routing

- Route & Fill

- Excluding Parts For MPR (multi-point routing)

- Excluding Groups For MPR

- Sticky Move

- Service Exchange

- Reporting

- Data Exporting

- Plant3D to Revit Workflows

- Autodesk Inventor

- Civil3D Consultation and Guidance

- Ducting and Piping Machine configurations

- Fabrication Shop – Layout optimization

- Fabrication Optimization Strategies

- Customized Solutions

- Process Redesign

- Technology Integration

- Wastage Material Reduction and more…