There is an overabundance of Autodesk® Fabrication CADmep™ content as well as numerous resources available for content creation. Unfortunately, the quality content seems to get lost in the shuffle. Incorrect or outdated dimensional data, missing model numbers, redundancies, and more can result in lower quality BIM content for use in Autodesk® Fabrication CADmep™.

There are several impacts that contractors face as a result:

- Significantly increased overall project costs

- Liability issues

- Reduced productivity

- Limited workflows due to lack of software integration

With these impacts, it is understandable that a contractor may lose trust in the Fabrication CADmep™ content that is available for download.

At ENGworks Global, we believe BIM content can be so much more than a download, and we take quality seriously. Here are the ways we approach quality for the content we create for use in Fabrication CADmep™.

What is considered quality content?

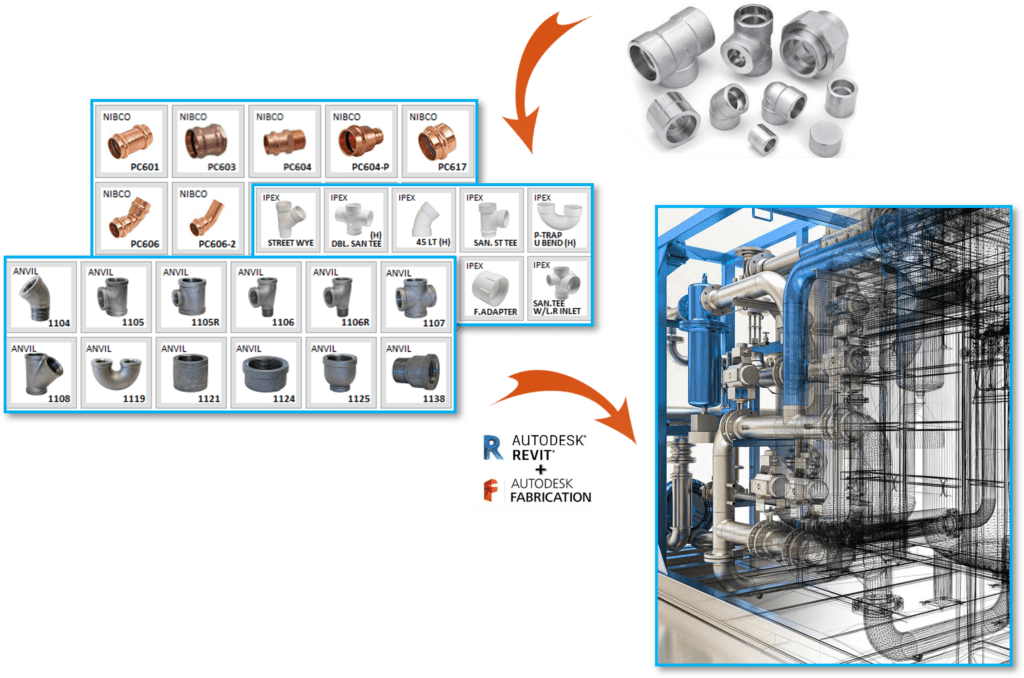

To qualify as a quality BIM product, Fabrication CADmep™ content needs to be accurate, consistent, and compatible with today’s software needs.

Accuracy

With the increased use of Fabrication CADmep™ content in the BIM process, accurate content has become a need for modelers, engineers, and professionals. However, we know that is not a simple task because there is a lot of data out there that might have been created for different uses, etc. This creates additional costly challenges. According to an article from Harvard Business Review, knowledge workers waste 50% of their time in “hidden data factories, hunting for data, finding and correcting errors, and searching for confirmatory sources for data they don’t trust.” (Redman, 2017).

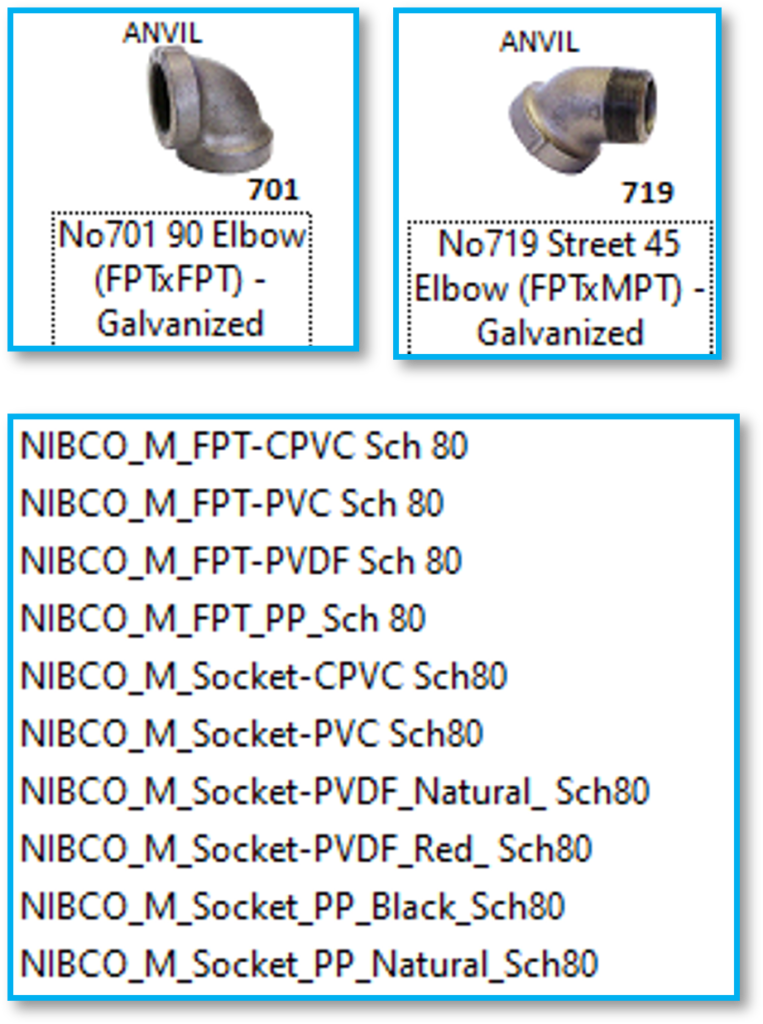

We actively work in collaboration with various manufacturing teams. In doing so, we can ensure that all data used is certified by the manufacturer and that it originates from the engineering and other manufacturing teams for 100% accuracy.

Consistency

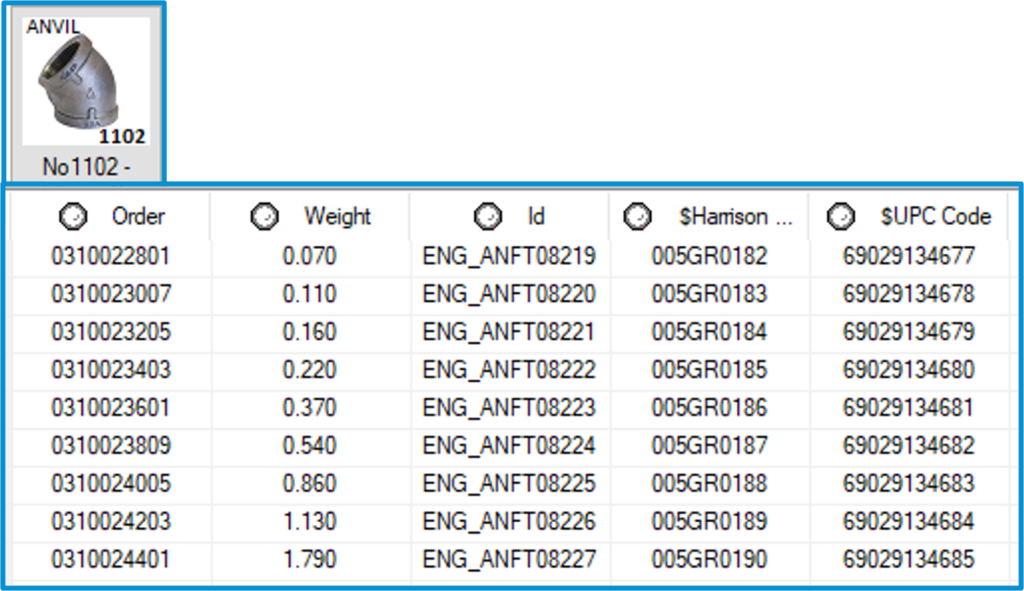

Consistency is an important aspect of quality across an entire library for a productive workflow. Without consistency, you risk snags and downtime on your projects. Fabrication CADmep™ content is considered consistent if an ITM’s connectivity, naming convention, product CID templates, and other factors are being utilized with best practices consistently. We incorporate product ID, dry weights, model numbers, UPC and HPH codes as the minimum metadata required for our content to meet and exceed end-user expectations.

Compatibility

Compatibility and functionality are two significant features expected in every fabrication part. A lot of content available in the market today is created with unique connectivity rules. This limits overall compatibility with out-of-the-box content and with content such as pipes and tubes. With the constant innovation and technological advances, all newly built content needs to be compatible with the latest software trends. This allows content to seamlessly fit in with the existing workflows.

Our Fabrication team continuously verifies our content to assure full functionality and software integration that suits state-of-the-art BIM processes.

Now that we’ve gone over several factors of quality involved with Fabrication CADmep™ content, it’s important to note that these are not individually independent considerations. All of these and more are part of our multi-faceted approach as we serve the industry. Our content is called certified Autodesk® Fabrication CADmep™ content because we know that focusing on the right things not just once but over time creates better outcomes.

Leveraging manufacturer certified content provides an enhanced user experience with the following features:

- Correct and applicable representation of parts

- Correct connections

- Correct installation capabilities

- Correct metadata needed for purchasing and estimate reports

Certified content provides significant benefits for design teams:

- Accurate bill of materials (BOM)

- Accurate installation drawings

- Accurate coordination with reduced field issues

- Accelerated time to production, installation, and beyond

Next Steps

The complicated nature of Autodesk® Fabrication CADmep™ content and the challenges associated with creating, managing, and updating it creates a gap that is tedious, risky, and expensive to bridge alone. ENGworks Global offers an all-encompassing service that involves all the necessary steps to provide your team with highly efficient quality content.

Letting us handle your content needs with our expertise will provide more time for your team to focus on modeling, estimation, and project management. We have over 15 years of experience in content creation along with an outstanding industry reputation. We pledge to provide unlocked quality with certified Fabrication CADmep™ content for better outcomes on your projects.

To learn more about our content creation, fabrication, and administration services, contact us at info@ENGworksGlobal.com

Sources Cited:

Redman, T. C. (2017, October 4). Bad Data costs the U.S. $3 trillion per year. Harvard Business Review. Retrieved May 26, 2022, from https://hbr.org/2016/09/bad-data-costs-the-u-s-3-trillion-per-year

Autodesk Trademark Notice:

Autodesk, the Autodesk logo, Revit, and Fabrication CADmep are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries.

This publication is independent of Autodesk, Inc., and is not authorized by, endorsed by, sponsored by, affiliated with, or otherwise approved by Autodesk, Inc.

The ENGworks Global Team

Please also connect with us on our social media platforms below to stay up to date with our announcements.